What is a Wall Sheet and How is it Used in Construction?

In construction, the term "wall sheet" refers to a versatile building material. This material plays a crucial role in both structural integrity and aesthetic appeal. According to industry reports, the global wallboard market is projected to reach USD 61 billion by 2025, illustrating the growing importance of wall sheets in construction.

Wall sheets are often used in residential and commercial projects. They provide strength, insulation, and soundproofing benefits. Their lightweight nature simplifies the installation process. However, not all wall sheets are created equal. Some may fail to meet energy efficiency standards. This raises concerns about long-term performance and sustainability.

While wall sheets can enhance building design, challenges persist. The selection of appropriate materials depends on project requirements and environmental factors. Inadequate research can lead to costly mistakes. Overall, understanding wall sheets is vital for builders aiming for quality and durability in construction projects.

What is a Wall Sheet?

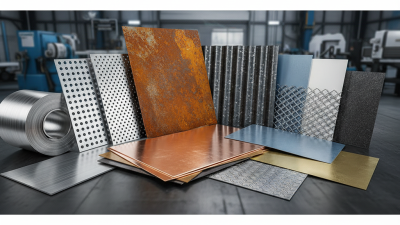

A wall sheet is a key component in construction. It refers to a flat, thin piece of material used to create partition walls, ceilings, or even facades. These sheets can be made from various materials like gypsum, plywood, or metal. Their versatility allows them to serve multiple purposes in a building project. In residential or commercial settings, wall sheets provide essential support and insulation.

Many builders overlook the importance of selecting the right type of wall sheet. Not all materials are suitable for every project. For instance, moisture-resistant sheets are vital in bathrooms, while fire-rated sheets are necessary in commercial spaces. Using the wrong type can lead to issues later. A wall sheet may appear simple, but the choice significantly impacts durability and safety.

Installation requires careful planning. Improper alignment or measurement can create problems. It’s essential to ensure that each sheet is securely fastened and fits well with adjacent sheets. Ignoring these details might seem minor, but they can affect the entire structure’s integrity. Wall sheets play a crucial role, and every decision counts in construction.

Types of Wall Sheets Used in Construction

Wall sheets are crucial in construction. They provide structural strength and insulation. Several types of wall sheets are commonly used, each serving different purposes.

Gypsum wall sheets are popular for interior use. They are lightweight and easy to install. These sheets are fire-resistant, making them ideal for safety.

On the other hand, plywood wall sheets offer durability. They are often used in load-bearing walls. Plywood can withstand heavy loads but requires proper treatment to ensure longevity.

Metal wall sheets are another option. They are usually made from steel or aluminum. These sheets are weather-resistant and great for exteriors. However, they may rust over time if not maintained properly.

Lastly, fiber cement wall sheets combine durability with aesthetics. They mimic wood but require less maintenance. Each type has unique benefits and limitations. Choosing the right one is essential for any construction project.

Applications of Wall Sheets in Building Projects

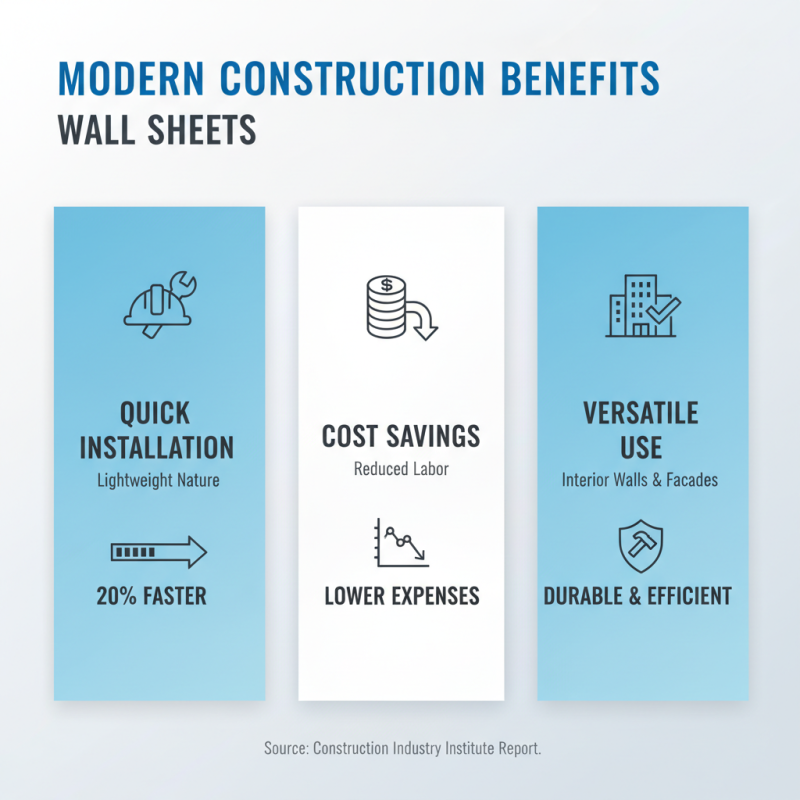

Wall sheets play a crucial role in modern construction projects. They are primarily used for creating interior walls and facades. Their lightweight nature simplifies installation, making them a popular choice among builders. According to a report by the Construction Industry Institute, wall sheets can reduce construction time by up to 20%. This efficiency may lower labor costs significantly.

In building projects, wall sheets are utilized in various ways. They are essential for sound insulation. For example, residential buildings often use them to minimize noise between apartments. Reports show that utilizing wall sheets for soundproofing can enhance comfort and satisfaction. In addition, wall sheets offer aesthetic flexibility. They can mimic the look of traditional materials without the added weight or cost.

However, the choice of wall sheets is not always straightforward. Not all materials provide the same level of durability or insulation. Builders must consider factors like climate and building type. A poorly chosen wall sheet can lead to problems, like increased energy costs or structural issues. This inconsistency highlights the importance of careful selection and planning in construction processes.

Benefits of Using Wall Sheets in Construction

Wall sheets are versatile materials often used in construction projects. They are typically made from various materials such as metal, plastic, or composite materials. These sheets provide a durable and protective layer for walls. One of the main benefits is their ease of installation. Workers can quickly apply them to any surface. However, proper alignment is crucial. If not installed correctly, gaps might appear.

Another significant advantage is insulation. Wall sheets can help maintain temperature within a building. They prevent heat loss during winter and keep spaces cool in summer. This can lead to energy savings over time. Yet, choosing the right insulation type can be challenging. Not every sheet offers the same level of thermal performance.

Additionally, wall sheets have aesthetic benefits. They come in various colors and finishes. This allows for creativity in design. Architects often use them to enhance a building's appearance. However, not all options are weather-resistant. In certain climates, the durability of the finish can be questionable. Attention to detail is essential when selecting materials for long-term use.

Installation Process for Wall Sheets in Construction

Wall sheets are essential in construction, providing structural integrity and insulation. The installation process requires careful planning and precise execution. To begin, workers must prepare the wall frame. This includes measuring and cutting wall sheets to the desired dimensions. Using accurate measurements ensures a snug fit, crucial in preventing gaps that can lead to energy loss.

A layer of adhesive is often applied to the wall frame. This enhances the bond between the wall sheet and the frame. Next, workers typically attach the wall sheets using screws or nails. Proper spacing is critical. It's common to install sheets every 12 to 16 inches to ensure stability. The joints between sheets should be staggered to enhance strength. According to recent reports, improper installation can reduce insulation effectiveness by up to 30%.

Tip: Always wear protective gear. Safety glasses and gloves can prevent injuries during installation.

After the panels are installed, surface finishing is next. This includes sealing joints and applying texture if required. While some may rush this step, it’s vital for durability. Remember, a rushed finish can lead to premature wear. Investing time in this phase can enhance the wall’s lifespan and aesthetics.

Tip: Double-check measurements before cutting. Errors at this stage can result in wasted materials and extra costs.

What is a Wall Sheet and How is it Used in Construction? - Installation Process for Wall Sheets in Construction

| Dimension | Description | Typical Use |

|---|---|---|

| Material Type | Drywall, Plywood, MDF | Interior and Exterior Walls |

| Thickness | 1/2 inch, 5/8 inch | Residential and Commercial Settings |

| Installation Method | Nailing or Screwing | Framed Construction |

| Finishing Techniques | Taping, Mudding, Sanding | Interior Walls for Painting or Wallpaper |

| Fire Resistance | Type X Gypsum Board | Commercial Buildings and Warehouses |

| Moisture Resistance | Moisture-Resistant Board | Bathrooms and Kitchens |

Related Posts

-

How to Choose the Best Aluminum Roof for Your Home in 2025

-

2026 Best Metal Manufacturing Innovations for Industry Growth?

-

Top Metal Manufacturing Techniques Transforming the Industry Today?

-

10 Essential Tips for Choosing the Best Roof Panels for Your Home

-

Top 10 Sheet Metal Types and Their Unique Applications for Your Projects

-

How to Properly Install Metal Roof Flashing: A Step-by-Step Guide