Top Metal Manufacturing Techniques Transforming the Industry Today?

The landscape of metal manufacturing is undergoing rapid transformation. According to a recent report by MarketsandMarkets, the global metal fabrication market is expected to reach $23.20 billion by 2025. This growth reflects a shift in production techniques and technologies. Industry leaders are leveraging innovative methods to increase efficiency and reduce waste.

Advanced techniques like additive manufacturing and CNC machining are reshaping traditional processes. Additive manufacturing, for example, allows for intricate designs that were previously impossible. It reduces material waste significantly. However, the integration of these technologies comes with challenges. The need for skilled labor and the adaptation of existing facilities can be substantial hurdles.

As metal manufacturing evolves, companies must adapt to remain competitive. Staying updated with these trends is crucial. Embracing new technologies can lead to better product quality and faster turnaround times. However, the cost of implementation and the learning curve can be daunting. Industry stakeholders must navigate these complexities to fully leverage the benefits of modern techniques.

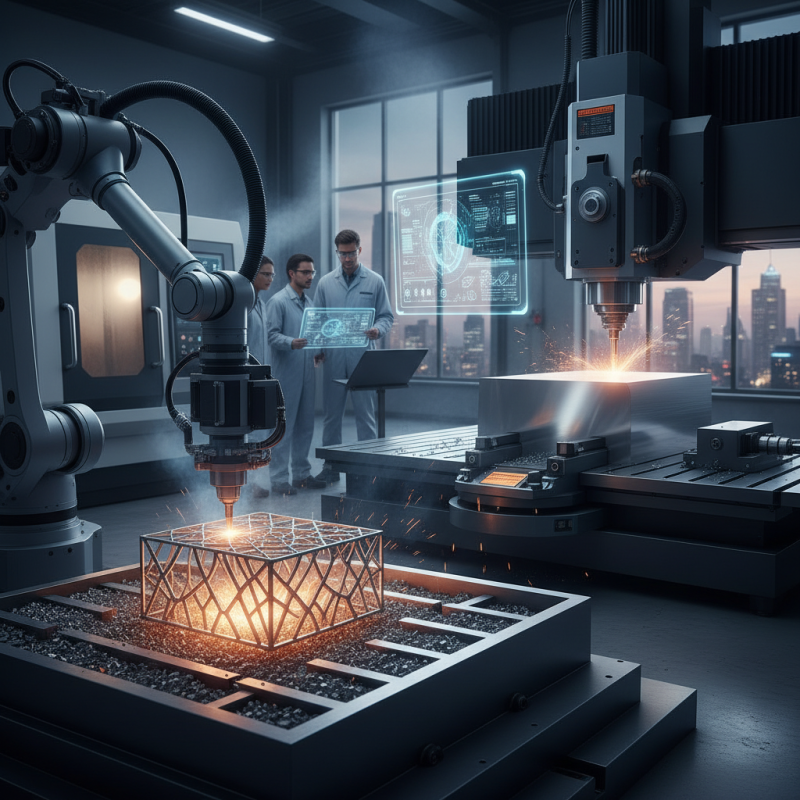

Innovations in Metal 3D Printing: Expanding Manufacturing Capabilities

Metal 3D printing is reshaping the manufacturing landscape. This technology enables the creation of intricate designs that are challenging for traditional methods. With additive manufacturing, layers of metal are fused together, allowing for high precision and customization. A component can now be produced in hours instead of weeks.

However, challenges remain. The process can be expensive and requires skilled operators. Not every metal type performs well in 3D printing. Sometimes, the properties of printed metals do not match those produced traditionally. This calls for continuous research and improvement in the field. Manufacturers must also ensure that they can handle the quality control of these new processes. As the technology matures, the potential for innovation grows immensely.

Moreover, industries are exploring various applications. Aerospace, automotive, and medical devices show particular promise. Each application has unique requirements. Metal 3D printing allows for lighter structures, which is crucial in aerospace. Yet, each step forward brings reflections on durability and strength. The current state of fusion and melting techniques requires more refinement to meet global standards. The journey of metal 3D printing is just starting, making it an exciting frontier in modern manufacturing.

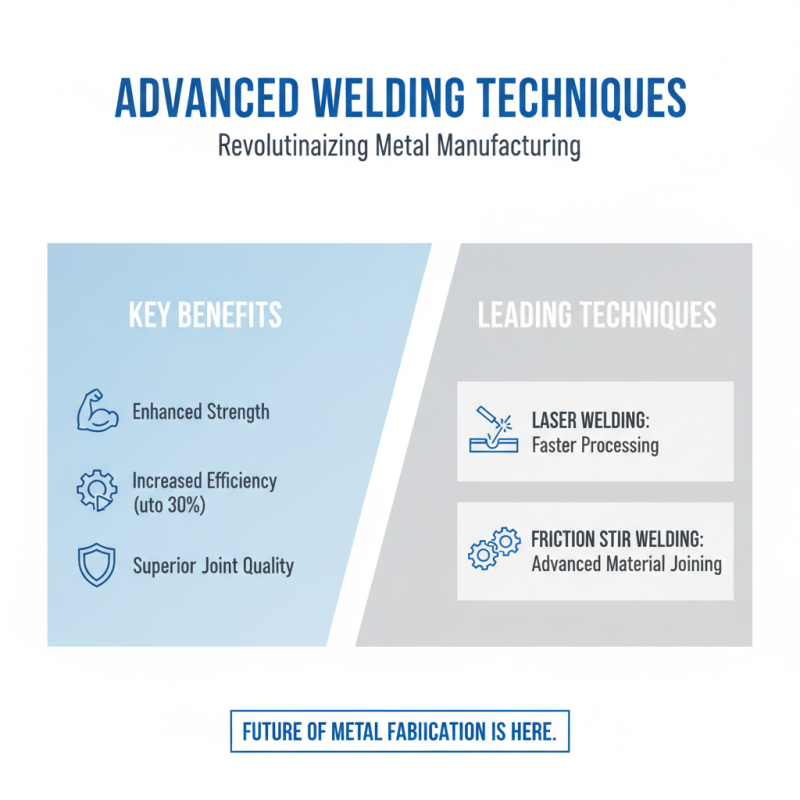

Advanced Welding Techniques: Enhancing Strength and Efficiency

Advanced welding techniques are revolutionizing metal manufacturing. These methods improve both strength and efficiency. According to a recent market report, advanced welding technologies could increase production efficiency by up to 30%. Techniques such as laser welding and friction stir welding are becoming more prevalent. They offer faster processing times and superior joint quality compared to traditional methods.

Laser welding, in particular, is noteworthy. It focuses energy precisely, creating narrow heat-affected zones. As a result, this minimizes distortion and improves mechanical properties. Furthermore, a study highlights that laser welding can decrease energy consumption by 20%. Such advancements push the industry toward sustainability while enhancing product performance.

However, the transition to advanced techniques is not without challenges. Many manufacturers face a skills gap in their workforce. Training programs must adapt quickly to teach new technologies effectively. Additionally, the initial investment in these advanced systems can be significant. Some firms may struggle to justify the costs, especially in a competitive market. Balancing innovation and practicality remains a critical concern as the industry evolves.

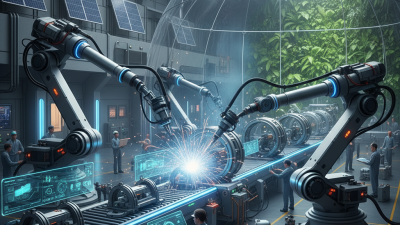

Automation and Robotics in Metal Manufacturing: Increasing Productivity

Automation and robotics are reshaping metal manufacturing today. These technologies enhance speed and precision. Robots can perform repetitive tasks tirelessly, reducing human error. For instance, welding and cutting jobs rely more on robotic arms. These machines ensure consistent quality across production runs.

Yet, the transition isn't flawless. Many workers are concerned about job displacement. Companies must balance automation and human expertise. Robots lack the creativity and intuition of skilled workers. Moreover, initial investments in automation can be steep. Without proper planning, costs may outweigh benefits.

The integration of smart technologies is also a challenge. Systems need constant updates and maintenance. Machines require skilled operators who understand both the tech and the craft. Training programs must evolve to meet these needs. In some cases, companies struggle to adapt. Emphasizing a collaborative approach is crucial. Blending human insight with robotic efficiency can maximize productivity in metal manufacturing.

Sustainable Practices in Metal Production: Reducing Waste and Carbon Footprint

Sustainable practices in metal production are gaining momentum. Many manufacturers are adopting innovative techniques to reduce waste and carbon footprints. According to a recent industry report, up to 30% of metal waste can be minimized using advanced recycling methods. These methods include the use of electric arc furnaces, which are more energy-efficient than traditional blast furnaces.

In addition, implementing closed-loop systems can enhance sustainability. Studies show that utilizing recycled scrap versus primary materials can reduce greenhouse gas emissions by 60%. However, not all companies are on board. Some still rely on outdated methods, leading to higher waste levels. The challenge lies in educating businesses about these modern techniques.

Operational changes are essential. Many facilities struggle with implementing new technologies. Training staff can be resource-intensive. But investing in these sustainable methods often yields long-term savings. As the industry evolves, it faces a balancing act between profitability and environmental responsibility. Sustainable practices are not a mere trend; they represent the future of metal manufacturing.

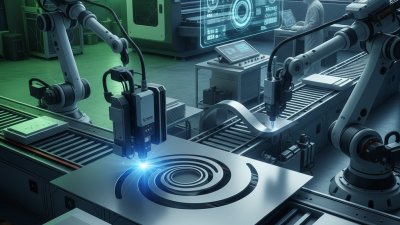

Smart Manufacturing and IoT: Transforming Metal Industry Efficiency

Smart manufacturing and the Internet of Things (IoT) are reshaping the metal industry. According to recent reports, integrating IoT in manufacturing can improve efficiency by 30%. This shift is not just about technology; it’s about creating a connected environment. Sensors and data analytics provide insights that help reduce waste. Companies can monitor machinery in real-time, catching issues before they escalate.

Adopting smart manufacturing techniques is crucial. Companies are seeing productivity gains while cutting costs. A study indicated that manufacturers implementing IoT solutions can save up to 20% on operational costs. However, not all organizations experience these benefits immediately. Transition can be challenging, requiring a shift in mindset and skill sets.

Tip: Invest in employee training. This ensures your team adapts smoothly to new technologies. Communication is key. Engage employees in the process to build a culture of innovation.

Tip: Start small. Pilot projects allow companies to test the waters. Gather data, learn, and expand gradually. This cautious approach helps mitigate risks while embracing the future of manufacturing.

Related Posts

-

How to Start a Metal Workshop for Beginners?

-

2026 Best Metal Manufacturing Innovations for Industry Growth?

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

Top 5 Benefits of Choosing Aluminum Roofs for Homeowners in 2023 with Industry Insights on Longevity and Energy Efficiency

-

How to Choose the Best Aluminum Roof for Your Home in 2025