Essential Guide to Metal Roof Flashing Techniques and Benefits

Metal roof flashing is a critical aspect of roofing that ensures durability and protection. John Smith, a leading expert in the roofing industry, emphasizes, “Proper flashing prevents water damage and extends the life of your roof.” This highlights the essential role of metal roof flashing in maintaining structural integrity.

Flashing acts as a barrier against water infiltration at joints and seams. It mitigates leaks, which can cause extensive damage over time. However, many property owners overlook its importance. This oversight can lead to costly repairs down the line.

Choosing the right techniques and materials for metal roof flashing is vital. For instance, using aluminum or galvanized steel can enhance longevity. Yet, improper installation might negate these benefits. Attention to detail during the installation phase is crucial. Small mistakes can lead to big consequences. Investing time in understanding metal roof flashing techniques is worth it for lasting protection.

Overview of Metal Roof Flashing and Its Importance

Metal roof flashing is a critical component of roofing systems. It helps direct water away from seams and joints. Proper flashing prevents leaks and water damage. It’s essential for longevity and performance. Failing to install flashes correctly can lead to major issues. A small mistake could result in significant water intrusion.

When installing metal roof flashing, consider these tips. Choose high-quality materials to ensure durability. Ensure the flashing overlaps properly at seams. This technique helps protect vulnerable areas from water exposure. Regular inspections can identify potential problems early. Keep an eye on the edges and joints for wear and tear.

Sometimes, even skilled installers face challenges. Improperly measuring flashings is a common mistake. Small miscalculations lead to costly repairs later. Take time during installation to verify measurements. It’s worth the effort to secure your investment. Flashing matters more than it seems at first glance.

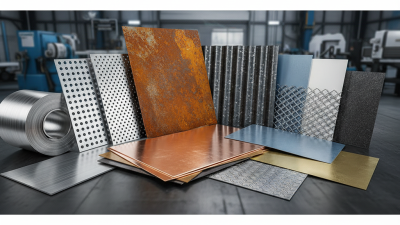

Types of Flashing Materials Used in Metal Roofing

When it comes to metal roofing, flashing materials play a critical role. The right flashing ensures water runs off correctly, protecting the roof from leaks. Common materials include aluminum, steel, and copper. Each type has its pros and cons.

Aluminum is lightweight and resistant to corrosion. However, it can be less durable than other options. Steel is strong but may rust if not properly coated. It's essential to consider the climate and specific roofing needs when choosing.

Copper flashing stands out for its longevity and aesthetic appeal. It develops a green patina over time, which some homeowners find charming. Yet, its higher cost can be a barrier for many. Non-metal options like PVC or rubber are also available. They are flexible, making installation easier. Still, they may not last as long as metal counterparts.

Choosing the wrong material can lead to costly repairs and leaks. It is crucial to evaluate each option carefully and reflect on budget and maintenance.

Step-by-Step Guide to Installing Metal Roof Flashing

Installing metal roof flashing requires careful planning and execution. The right techniques ensure durability and protect against water damage. According to industry reports, improper flashing installation can lead to leaks, causing costly repairs. Metal roof flashing directs water away from vulnerable areas, such as chimneys and vents. Ensuring a tight seal during installation is crucial.

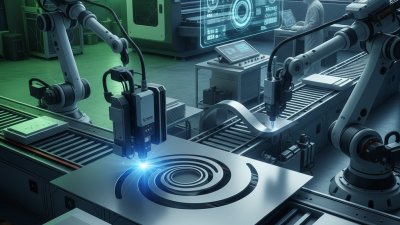

Begin by measuring the areas where flashing will be installed. Use high-quality materials that suit your roof type. Use a tin snip to cut the flashing to the required size. Attach it with roofing screws, ensuring they are properly aligned and watertight. Overlapping sections correctly is essential. Industry studies suggest that 30% of roof-related issues stem from faulty flashing.

Consider the weather conditions during installation. Wind or rain can impact the adhesion and sealing process. Always check the local weather forecast before starting. It’s important to remember that even small gaps can lead to significant problems. Ensure that flashing is maintained regularly for optimal performance. Practice and dedication can turn a challenging task into a straightforward one.

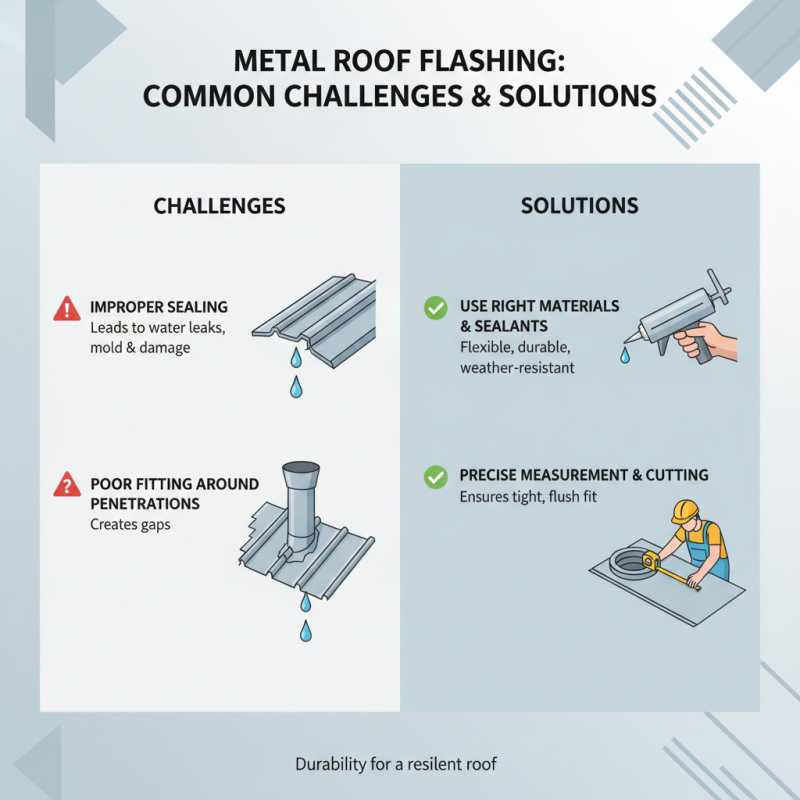

Common Challenges in Metal Roof Flashing and Solutions

Metal roof flashing is crucial for durability. However, common challenges often arise during installation. One frequent issue is improper sealing. Without a proper seal, water can seep in. This can lead to mold and structural damage. During installation, ensure you use the right materials. Inconsistent flashing can also result from poor fitting around roof penetrations. When not aligned correctly, it can create gaps.

Another challenge is corrosion over time. Metal flashing is exposed to harsh weather. Regular inspections are essential. When you spot rust or deterioration, address it quickly. Neglecting these signs can escalate issues down the line. Many homeowners overlook these details. Simple fixes can prevent more significant problems. Emphasizing quality in your flashing installation will pay off in the long run. Regular maintenance checks can prolong the life of your metal roof.

Benefits of Proper Metal Roof Flashing Techniques

Metal roof flashing is a crucial component that protects your home from water damage. When done correctly, it directs water away from vulnerable areas, preventing leaks and erosion. Poor flashing installation can lead to costly repairs. This makes understanding proper techniques essential for any roofing project.

Tips for effective metal roof flashing include proper sizing and installation. Flashing should extend at least 6 inches beyond the area it protects. Ensure that it's angled away from the roof to guide water off effectively. Also, regularly check the flashing for any signs of wear or damage. This proactive approach can save you time and money down the line.

One common mistake is neglecting to seal the flashing adequately. Using high-quality sealants can make a significant difference. Don't rush the sealing process; take your time to ensure every seam is tight. Remember, visible gaps can lead to serious leaks. Reflect on your installation methods and make necessary adjustments to improve performance.

Essential Guide to Metal Roof Flashing Techniques and Benefits

| Flashing Technique | Description | Benefits | Recommended Materials |

|---|---|---|---|

| Continuous Flashing | A long piece of metal that covers joints where two surfaces meet. | Prevents leaks, provides a seamless transition. | Aluminum, Copper |

| Step Flashing | Individual pieces that interlock at the roof and wall junctions. | Effective at shedding water, allows for expansion and contraction. | Galvanized Steel, Aluminum |

| Valley Flashing | Used at roof valleys to guide water down to the gutters. | Prevents water pooling, enhances water drainage. | Copper, Stainless Steel |

| Counter Flashing | Installed over wall flashings to provide added waterproofing. | Improves durability, prevents moisture infiltration. | Aluminum, Copper |

Related Posts

-

How to Properly Install Metal Roof Flashing: A Step-by-Step Guide

-

Top 5 Benefits of Choosing Aluminum Roofs for Homeowners in 2023 with Industry Insights on Longevity and Energy Efficiency

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

2025 How to Choose the Best Aluminum Roof Panels for Your Home Renovation

-

How to Choose the Best Aluminum Roof for Your Home in 2025

-

Top 10 Sheet Metal Types and Their Unique Applications for Your Projects