2026 Best Metal Manufacturing Techniques and Innovations?

The world of metal manufacturing is evolving rapidly. With advancements in technology, new techniques are emerging. Renowned expert Dr. Emily Carter emphasizes, "Innovation is the lifeblood of metal manufacturing." This statement resonates as industries seek efficiency and sustainability.

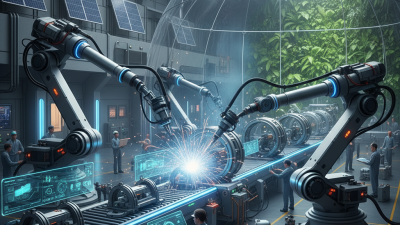

In 2026, the focus will be on integrating automation and smart technologies. Metal manufacturing techniques like additive manufacturing and precision machining are gaining traction. These innovations not only enhance production but also reduce waste. However, challenges remain. The industry must find balance between automation and skilled labor.

Understanding the complexities of metal manufacturing is crucial. While new techniques show promise, there are risks too. Companies must invest in training programs to keep up. Future growth depends on embracing change while retaining valuable craftsmanship. Balancing these elements will shape the future of metal manufacturing.

Overview of Metal Manufacturing Techniques in 2026

In 2026, metal manufacturing techniques have evolved significantly. Advanced technologies drive the industry forward. The global market for metal manufacturing is projected to exceed $280 billion. Efficient production methods are vital for meeting demand. Automation and robotics feature prominently in modern factories. They enhance precision and reduce human error, but reliance on these systems raises concerns.

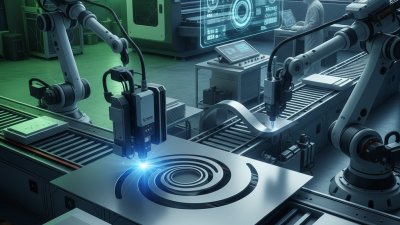

Additive manufacturing, or 3D printing, plays a key role. This technique allows for complex geometries, which traditional manufacturing cannot achieve. A report notes that this segment could grow by over 25% annually. However, challenges exist, such as material limitations and high costs. Manufacturers often find it difficult to balance innovation with budget constraints.

Sustainability is another growing focus. Metal recycling rates are improving, reaching nearly 70% in some sectors. Yet, issues with energy consumption remain. It is essential to rethink energy sources and production methods. Some innovations, while promising, may not be viable long-term. Continuous improvement is necessary for the industry's future success.

Emerging Innovations in Metal Processing Technologies

Emerging innovations in metal processing technologies are transforming the manufacturing landscape. Advanced techniques like additive manufacturing are now gaining traction. This method builds metal parts layer by layer, which reduces waste significantly. Companies can create complex shapes that were impossible before. Despite the promise, challenges remain. Not all metals are suitable for this process.

Another innovation is automation in metalworking. Robots are increasingly involved in precision tasks. They enhance efficiency and reduce human error. However, integrating these machines into existing workflows can be complex. Workers need retraining to adapt. There’s also a question of job displacement.

Sustainability is becoming a key focus. New technologies aim to recycle metals more efficiently. This adds value to scrap material while lowering the carbon footprint. Yet, the economic viability is still under examination. Balancing innovation with practicality is crucial. As we explore these advancements, continuous reflection on their implications is necessary.

2026 Best Metal Manufacturing Techniques and Innovations

| Technique/Innovation | Description | Benefits | Applications | Emerging Trends |

|---|---|---|---|---|

| Additive Manufacturing | Technology that builds 3D objects layer by layer from CAD models. | Customization, reduced waste, complex geometries. | Aerospace, automotive, medical devices. | Integration with AI, improved materials. |

| Advanced Robotics | Use of robots for precision manufacturing and assembly. | Increased efficiency, reduced labor costs, enhanced safety. | Heavy machinery, electronics, consumer goods. | Collaboration between humans and robots, smart factories. |

| Laser Cutting | Using high-powered lasers to cut and engrave materials. | Precision, speed, and minimal material damage. | Metal fabrication, signage, artistic designs. | Automation of processes, enhanced beam quality. |

| Metal 3D Printing | Process of creating metal parts directly via 3D printing technology. | Reduced lead times, flexibility in designs. | Tool manufacturing, aerospace components. | Continued innovations in metal powders and processes. |

| Smart Manufacturing | Integration of IoT and AI in manufacturing processes. | Real-time data analysis, predictive maintenance. | Manufacturing floors, supply chain optimization. | Increased connectivity, data-driven decisions. |

Sustainable Practices in Modern Metal Production

Sustainable practices in metal production are gaining traction. Manufacturers now face the challenge of reducing waste and energy consumption. Many techniques are evolving to address environmental concerns. For instance, recycling metal materials helps minimize resource extraction. This shift not only supports sustainability but also reduces costs.

Innovative methods like additive manufacturing are changing the landscape. These processes often use less material compared to traditional methods. They allow for complex designs, which can lead to less waste during production. However, some companies still struggle to implement these techniques effectively. Training and investment are crucial for successful adaptation.

Embracing sustainability requires a cultural shift. Workforces must prioritize eco-friendly solutions. Collaboration across industries is essential for knowledge sharing. Yet, consistent practices can be difficult to maintain. There is still much room for improvement. Finding the right balance between efficiency and sustainability remains a challenge.

2026 Best Metal Manufacturing Techniques and Innovations

Automation and Robotics in Metal Manufacturing

Automation and robotics are revolutionizing metal manufacturing. These technologies improve efficiency and precision. Robots handle tasks like welding and assembly. This reduces human error, leading to higher quality products. For instance, robotic arms can work continuously with speed. However, implementing them is not always seamless.

Some manufacturers face challenges. Integrating new systems requires skilled workers. Training staff can prove time-consuming and costly. Additionally, there is anxiety about job displacement. Workers may fear losing their roles to machines. Balancing automation with employment is a sensitive issue.

Despite these hurdles, the potential rewards are significant. Companies can achieve greater output and reduced waste. Automation allows for more complex designs that humans might struggle with. Yet, finding the right balance between technology and human touch remains essential. As the industry moves forward, reflection on these issues will guide better practices.

Quality Control Measures for Advanced Metal Products

In today's advanced metal manufacturing landscape, quality control is paramount. Effective measures ensure that metal products meet high standards. One crucial method is the rigorous testing of materials at multiple stages. For instance, tensile tests can reveal weaknesses in metal alloys. These tests prevent subpar products from reaching consumers.

Visual inspections also play a vital role in quality assurance. Trained technicians examine surfaces for flaws. However, human error can sometimes lead to oversights. Automated imaging technology can complement this process. It can detect imperfections that may go unnoticed by the naked eye.

Data analysis is another innovative approach to quality control. By tracking production metrics, manufacturers can identify trends. Regular audits of this data can pinpoint areas needing improvement. Yet, reliance on data may overlook unique challenges in production. Balancing technology with skilled craftsmanship remains essential for achieving excellence in advanced metal products.

Related Posts

-

How to Start a Metal Workshop for Beginners?

-

2026 Best Metal Manufacturing Innovations for Industry Growth?

-

Top Metal Manufacturing Techniques Transforming the Industry Today?

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

How to Choose the Best Sheet Metal Roof Panels for Your Home in 2025