2026 Best Metal Manufacturing Innovations for Industry Growth?

The metal manufacturing industry stands on the brink of a transformative era. Innovations are reshaping processes and products. Advanced techniques promise improved efficiency and sustainability.

As we delve into the best inventions for 2026, we must examine not only the technology but the challenges they bring. For example, automation could reduce costs but may lead to job losses. The balance between progress and social impact is delicate.

Sustainable practices are also key. While new materials offer exciting possibilities, their environmental footprint deserves scrutiny. Metal manufacturing innovations must not only enhance productivity but also promote a greener future. Addressing these issues is vital for long-term growth and responsible development.

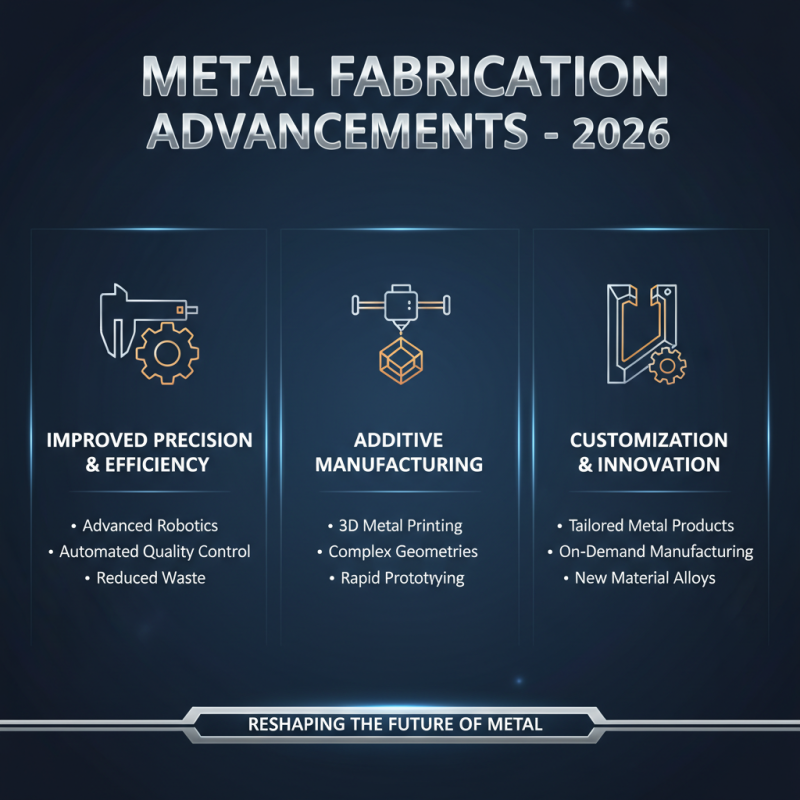

Advancements in Metal Fabrication Techniques for 2026

Advancements in metal fabrication techniques are set to propel the industry forward in 2026. Innovative methods are being developed to improve precision and efficiency. Techniques like additive manufacturing are reshaping traditional approaches. They allow for more complex geometries, which were previously difficult or impossible to achieve. This opens doors for customization in metal products.

Automation plays a key role in this evolution. Smart machinery is becoming more prevalent. These machines can reduce human error and increase production speed. Yet, the reliance on technology raises concerns. Workers may need to adapt or upskill to meet new demands. Not every company is ready for this shift. There are hurdles in integrating smart technologies seamlessly into existing workflows.

Sustainability is also a vital consideration. Advanced recycling techniques are being explored to minimize waste. However, the implementation can be inconsistent across the industry. Some companies are ahead, but others lag significantly. Striking a balance between innovation and practicality is challenging. The landscape will continue to evolve as these fabrication techniques develop further.

Emerging Technologies in Metal 3D Printing

Metal 3D printing is changing the game in manufacturing. This technology allows for unique geometries that traditional methods cannot achieve. Complex designs can be created with precision.

It reduces material waste, a significant advantage. However, the high cost of equipment often hinders widespread adoption. Many companies are hesitant to invest. The initial learning curve also presents challenges that can be daunting for some.

Recent innovations include new alloys specifically designed for 3D printing. These materials perform better under stress and heat. They open up new possibilities in aerospace and medical fields. Yet, the technology is still evolving.

Quality control remains an issue. Parts may not meet desired specifications every time. This inconsistency can impact reliability, complicating customer trust.

The future of metal manufacturing relies on these innovations. As more companies explore 3D printing, solutions will emerge for existing challenges. Collaboration between industries can lead to breakthroughs. The journey isn't straightforward, and there’s much to learn. Embracing these changes requires flexibility and forward thinking. Still, the potential for growth is undeniable.

Sustainable Practices in Metal Manufacturing

Sustainable practices in metal manufacturing aim to reduce waste and energy use. Many facilities are now investing in eco-friendly technologies. Recycling metal scrap is a key practice. It not only conserves resources but also decreases pollution.

Tips: Consider using renewable energy sources. Solar and wind power can significantly lower carbon footprints.

Water conservation is also crucial. Efficient cooling systems can reduce water wastage. Some manufacturers have started reusing water in their processes. This change can lead to significant savings.

Embracing sustainable practices may seem challenging. It requires investment and commitment. Some companies struggle to change existing mindsets. However, the long-term benefits are undeniable. It’s not just about immediate gains; it’s about a healthier future for all.

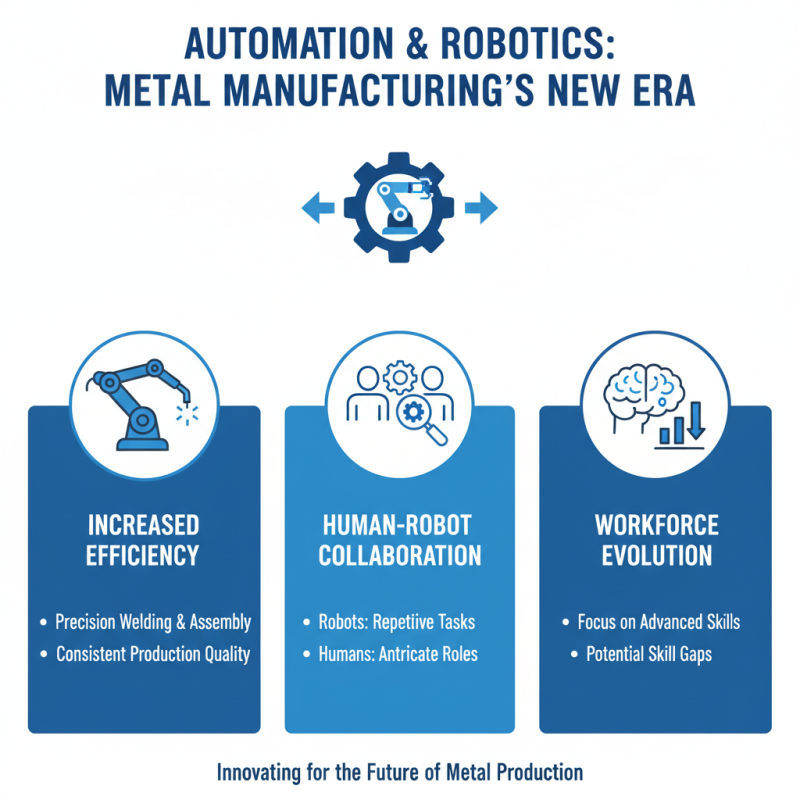

Automation and Robotics: Transforming Metal Production

Automation and robotics are changing the landscape of metal manufacturing. Factories now utilize advanced robotic systems for tasks like welding and assembly. This shift increases precision and consistency in production. Workers benefit too; machines handle repetitive tasks. This separation allows human labor to focus on more intricate roles. However, the reliance on automation can lead to skill gaps in the workforce.

While robotics improves efficiency, it also raises concerns about job displacement. Workers may feel uncertain about their future roles. Manufacturers need to address this issue. Training programs are essential for upskilling employees. Emphasizing collaboration between humans and machines might create a balanced environment.

Anecdotes suggest that factories integrating automation are seeing production times decrease. Yet, it's crucial to assess the quality of the output. Sometimes, robots might not adapt well to unexpected situations. This unpredictability can lead to errors. Balancing technology with human insight is key for sustainable growth in the metal industry.

Industry Collaborations Driving Innovations in Metal Manufacturing

The landscape of metal manufacturing is evolving rapidly, driven by collaborations within the industry. Companies are forming partnerships to share knowledge and resources. These alliances spark innovative ideas and solutions, which can lead to greater efficiency in production.

Tip: Engage with other industries to discover new methods. A fresh pair of eyes can often highlight pitfalls we overlook.

One notable trend is the integration of data analytics and artificial intelligence in production processes. Manufacturers are collecting data from various sources to enhance decision-making. This approach helps reduce waste and improve quality. However, not all companies fully embrace these tools yet. There are still fears of technology replacing jobs.

Tip: Invest in training for your team to build confidence with new tools. Transitioning can be uncomfortable, but it's essential for progress.

Ultimately, collaboration can sometimes lead to miscommunication. It's important to establish clear goals and expectations at the start. Teams must be aligned to ensure the best outcomes. Strengthening communication channels should be a priority for all involved.

2026 Best Metal Manufacturing Innovations for Industry Growth

| Innovation Type | Description | Impact on Industry | Collaborating Sectors |

|---|---|---|---|

| Additive Manufacturing | Utilizing 3D printing technology to create complex metal parts. | Reduces material waste and speeds up production times. | Aerospace, Automotive, Medical Devices |

| Smart Manufacturing | Integration of IoT to monitor and optimize metal manufacturing processes. | Enhances productivity and reduces downtime. | Electronics, Construction |

| Recycling Innovations | New processes for recycling metals efficiently. | Promotes sustainability and reduces raw material dependency. | Mining, Environmental Services |

| AI in Quality Control | Application of artificial intelligence for defect detection. | Improves product quality and reduces inspection costs. | Manufacturing, Quality Assurance |

| Advanced Coating Technologies | New coatings that enhance corrosion resistance and durability. | Extends the lifecycle of components and reduces maintenance costs. | Oil & Gas, Automotive |

Related Posts

-

How to Start a Metal Workshop for Beginners?

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

How to Choose the Best Aluminum Roof Panels for Your Home Upgrade Guide

-

Top 10 Benefits of Corrugated Metal Roofing for Your Next Construction Project

-

How to Choose the Best Sheet Metal Roof Panels for Maximum Durability and Energy Efficiency