Top 10 Applications of Sheet Metal in Modern Industry?

Sheet metal plays a crucial role in various modern industries. This versatile material is widely used due to its strength and flexibility. Its applications range from automotive manufacturing to electronics. Sheet metal is essential for creating durable and lightweight components.

In the automotive industry, sheet metal forms the body of cars and trucks. It enhances both the design and safety features of vehicles. In electronics, sheet metal enclosures protect sensitive components. The aesthetic design often relies on sheet metal finishes for a polished look.

However, the production and use of sheet metal are not without challenges. Environmentally, the manufacturing process can produce waste. Industries must find ways to reduce this impact. Nevertheless, the benefits of sheet metal in modern applications are significant and often outweigh the drawbacks. Its adaptability continues to shape the future of manufacturing.

Applications of Sheet Metal in Aerospace Engineering

Sheet metal plays a crucial role in aerospace engineering. Its versatility allows for the creation of lightweight and sturdy components. In fact, up to 50% of an aircraft's structure can be made from sheet metal. This includes fuselages, wings, and landing gears. The choice of materials, such as aluminum and titanium, enhances performance while reducing weight.

However, reliance on sheet metal also presents challenges. Manufacturing defects can occur, leading to structural weaknesses. For instance, a study highlighted that nearly 30% of metal components face quality control issues during production. Innovating new manufacturing techniques is essential. Continuous improvement in processes and quality assurance is vital to mitigate risks.

Moreover, aerospace engineers must balance cost and effectiveness. High-performance alloys can be expensive but necessary for safety. Each decision can drastically affect overall project budgets and timelines. Finding that balance remains a complex task. Flaws in design or execution can lead to significant setbacks, raising the stakes in this high-pressure industry.

Utilization of Sheet Metal in Automotive Manufacturing

Sheet metal plays a crucial role in automotive manufacturing. Its versatility and strength make it ideal for various components. For instance, sheet metal serves as chassis, body panels, and components in engines. According to a recent automotive industry report, around 70% of a vehicle’s structure is made from sheet metal.

This metal's lightweight nature helps reduce overall vehicle weight. A reduction of 10% in weight can improve fuel efficiency by up to 6%. Manufacturers face challenges with sheet metal forming. Achieving precise dimensions is not always easy, and imperfections can arise. For every 100 components produced, up to 5 may need rework due to these issues.

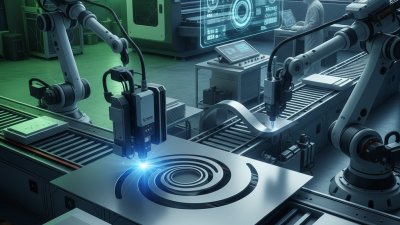

Using advanced techniques can enhance sheet metal application. CNC machining and laser cutting improve accuracy. However, implementing these technologies can be costly. In addition, the rapid evolution of electric vehicles creates new pressures on manufacturing processes. Companies must adapt to new designs and materials while optimizing existing sheet metal applications.

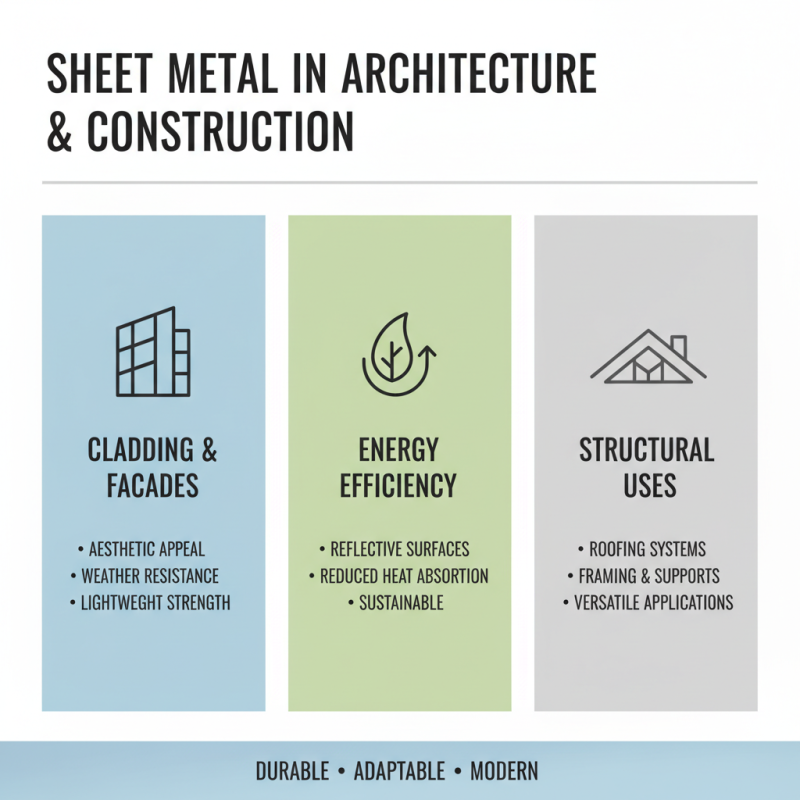

Sheet Metal Components in Construction and Architecture

Sheet metal is a versatile material widely used in construction and architecture. Its lightweight nature and strength make it ideal for various applications. Architects often favor sheet metal for cladding structures. It adds an appealing aesthetic while providing weather resistance. The reflective surfaces can enhance energy efficiency by reducing heat absorption.

In modern buildings, sheet metal is utilized in roofing systems. These roofs are durable and can last for decades. Proper installation is critical to prevent leaks and ensure longevity. There are challenges in achieving perfect seams, which can lead to maintenance issues down the line. Design flexibility is another advantage. Designers can customize shapes and sizes, allowing for unique building silhouettes.

However, there are considerations to keep in mind. Dents and scratches can mar the surface over time. Selecting the right finish is essential to minimize wear and tear. Moreover, local climate conditions play a significant role in sheet metal performance. Understanding these factors can aid in making informed decisions for future projects. Proper planning and execution are crucial for successful applications of sheet metal in architecture.

Role of Sheet Metal in Electronics and Appliances

Sheet metal plays a crucial role in the electronics and appliances industry. Its versatility is unmatched. In 2022, the global market for sheet metal in electronics reached approximately $20 billion. This trend is expected to grow by 5% annually. Manufacturers increasingly rely on sheet metal for its lightweight nature and durability.

Devices like smartphones and tablets benefit significantly from sheet metal enclosures. They provide essential protection while maintaining a sleek appearance. The use of aluminum, for instance, has increased due to its excellent thermal conductivity and lower weight. However, this shift may come with challenges. Not all electronics can exploit the full potential of sheet metal, leading to design limitations.

In appliances, sheet metal offers a cost-effective solution for housings and structural supports. It withstands high temperatures and is resistant to corrosion. Yet, achieving the perfect balance between aesthetics and functionality often necessitates compromises. Companies report that designing with sheet metal can be challenging. It requires careful consideration of manufacturing processes and material properties. Ultimately, while sheet metal is vital, continuous innovation is necessary to address its limitations effectively.

Top 10 Applications of Sheet Metal in Modern Industry

This chart illustrates the top 10 applications of sheet metal in modern industry, showcasing the percentage of usage across various sectors. The automotive industry leads with 25%, followed by electronics at 20%. Other sectors like aerospace and construction also heavily rely on this versatile material.

Innovative Uses of Sheet Metal in the Medical Industry

In the medical field, sheet metal has become an essential material. Its versatility allows for various applications, enhancing patient care and operational efficiency. Surgical tools, for example, often rely on precision-engineered sheet metal components. These instruments require durability and sharpness. The choice of material directly impacts performance and safety.

Sheet metal is also used in hospital furniture. Sturdy metal beds, carts, and cabinets offer lasting strength. Custom designs can fit specific needs, promoting better use of space. However, some designs may overlook patient comfort. This can lead to discomfort during long hospital stays, which needs more attention.

Another application is in medical devices. Sheet metal enclosures protect sensitive electronics. They shield devices from external elements. Yet, manufacturers must balance protection with weight. Overly heavy enclosures can make devices cumbersome. Finding the right balance is crucial for usability. Overall, while sheet metal offers many advantages in medical applications, continuous improvements are necessary.

Related Posts

-

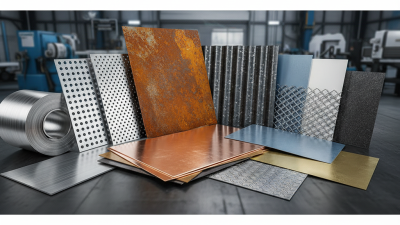

Top 10 Sheet Metal Types and Their Unique Applications for Your Projects

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

What is the Best Wall Sheet Material for Your Home?

-

How to Choose the Best Aluminum Roof for Your Home in 2025

-

Top 5 Benefits of Choosing Aluminum Roofs for Homeowners in 2023 with Industry Insights on Longevity and Energy Efficiency

-

How to Choose the Right Wall Sheet for Your Home Decor?