How to Start a Metal Workshop for Beginners?

Starting a metal workshop can be an exciting journey for beginners. John Smith, a metallurgical expert, once said, "The key to a successful metal workshop is passion and practice." This simple truth emphasizes that enthusiasm is essential as you dive into a new craft.

Creating your own metal workshop requires careful planning. Consider the space you need. Do you have room for tools and materials? Safety must be a priority. Remember, working with metal can be hazardous. Begin with basic tools like a dependable welder, cutting equipment, and protective gear. Each piece plays a role in your learning process.

Mistakes are part of the journey. Expect to face challenges while mastering techniques. Maybe your first weld won't be perfect. That's okay; reflection leads to improvement. Find joy in small victories and embrace the learning curve. The experience in your metal workshop will enhance your skills over time.

Understanding the Basics of Metalworking for Beginners

Starting a metal workshop can be exciting. Understanding metalworking is essential for beginners. Metalworking involves shaping, cutting, and joining metals. According to the Fabricators and Manufacturers Association, over 10 million people work in manufacturing in the U.S., with metalworking being a significant part.

Basic tools like a welder, grinder, and cutting torch are crucial. Safety gear is necessary. You need gloves, goggles, and ear protection. Metalworking can be dangerous, so awareness is vital. Beginners often overlook the importance of proper ventilation. Lack of airflow can lead to health issues.

Learning techniques like welding and forging can take time. Many beginners face challenges with precision and measurement. Mistakes happen and can lead to wasted materials. Being patient and practicing will improve skills. Workshops can be intimidating, but the rewards are worth it. Engaging in metalworking fosters creativity and problem-solving.

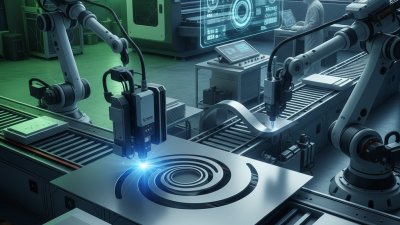

Essential Tools and Equipment for Your Metal Workshop

Starting a metal workshop requires essential tools and equipment. Understanding what you need is crucial for effective operations. Basic tools include a welder, metal cutting tools, and safety gear. Data shows that about 80% of beginners face challenges with the right equipment in the first year.

Welding tools are vital. They help in joining metals and can be complex. A beginner's welding setup can cost around $500, according to industry reports. Good safety gear should not be overlooked. A helmet, gloves, and boots protect against hazards. Investing in quality safety equipment is a must.

Tips: Focus on the basics first. Don't rush into buying high-end equipment. Start small and upgrade as skills improve. Take time to practice with each tool before moving on to more advanced tasks. Reflect on your setups. Is there something that feels uncomfortable? Maybe adjust your workspace layout. Comfort can boost productivity significantly.

How to Start a Metal Workshop for Beginners? - Essential Tools and Equipment for Your Metal Workshop

| Tool/Equipment | Purpose | Estimated Cost ($) | Essential for Beginners? |

|---|---|---|---|

| Arc Welder | Joining metal parts | 300 | Yes |

| Angle Grinder | Cutting and shaping metal | 100 | Yes |

| Bench Grinder | Sharpening tools and cleaning metal | 150 | Optional |

| Metal Shears | Cutting sheet metal | 200 | Yes |

| Safety Gear | Protecting from debris and heat | 100 | Yes |

| Tape Measure | Measuring lengths | 20 | Yes |

| Clamps | Holding materials in place | 40 | Yes |

Setting Up Your Metal Workshop: Space and Safety Considerations

When setting up a metal workshop, space and safety are critical. A well-ventilated area is essential. Reports indicate that poor air quality can harm respiratory health. A minimum of 300 square feet is recommended for beginners. This size allows for machinery, tools, and workspace. Clutter can lead to accidents, so keep the area organized and tidy.

Safety measures are vital. Always wear personal protective gear: goggles, gloves, and ear protection. The Occupational Safety and Health Administration (OSHA) states that personal protective equipment (PPE) reduces injury risk by 70%. Fire safety is also a concern. Install fire extinguishers and have clear exit routes. Inadequate emergency plans can escalate minor issues into serious incidents.

Consider your equipment layout. Keep heavy machinery on sturdy surfaces and away from walkways. This helps prevent tripping hazards. Electrical setups require attention too. Overloaded circuits are a fire hazard. Regularly check for wear and tear on cords and connections. Reflect on your setup periodically. Adjust as needed to improve both functionality and safety.

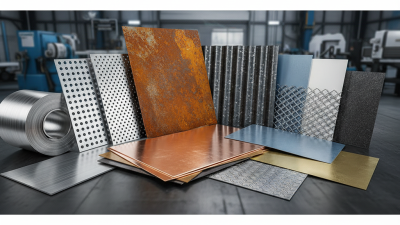

Finding and Selecting Appropriate Materials for Metal Projects

When starting a metal workshop, selecting the right materials is crucial. Beginners often overlook the importance of sourcing quality metal. According to industry reports, using subpar materials can lead to project failures and increased costs. For simple projects, aluminum and mild steel are great choices. They are affordable and easy to work with for novices.

Tip: Always check local suppliers for discounts. Bulk purchases can lead to significant savings. Scrap yards can be treasure troves for materials, reducing costs even further.

Understanding the properties of each metal is essential. For example, stainless steel is resistant to corrosion but difficult to weld. Copper is highly conductive but can be pricey. Balancing cost with workability is a challenge. It may take time to find the right fit.

Tip: Keep notes on how different materials perform in your projects. Documenting successes and failures will help refine your choices over time. Don't hesitate to experiment with various materials. Each experience builds your skill set.

Material Selection for Metal Projects

Learning Basic Techniques and Skills in Metalworking

Starting a metal workshop can be exciting. It's important to learn basic techniques and skills first. Understanding how metal behaves is essential. You’ll need to know about cutting, welding, and shaping. Each technique has its own tools and methods. For example, a simple handsaw can help cut sheets of metal. These initial steps will familiarize you with the materials.

Practice is key in metalworking. Try making small projects first. A basic metal box or a simple stand can be great starting points. Mistakes will happen, and that’s okay. Each error presents a learning opportunity. You might struggle with fitting parts together or finding the right angle while cutting. These challenges will develop your skills over time.

Safety is crucial in your workshop. Always wear protective gear. Gloves and goggles can prevent injuries. Creating a safe environment might take some time. You might need to rearrange your workspace as you discover what works. Stay patient and keep tinkering until everything feels right. Metalworking is as much about the process as it is about the final product.

Related Posts

-

2025 Top Trends in Sheet Metal Fabrication Technology and Applications

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

Top 10 Sheet Metal Types and Their Unique Applications for Your Projects

-

10 Essential Tips for Choosing the Best Roof Panels for Your Home

-

How to Choose the Best Sheet Metal Roof Panels for Your Home in 2025

-

How to Install an Aluminum Roof and Maximize Its Longevity