2025 Top Trends in Sheet Metal Fabrication Technology and Applications

In recent years, the sheet metal fabrication industry has experienced significant advancements, driven by technological innovations and evolving applications across various sectors. As we look toward 2025, it becomes increasingly important to identify and understand the top trends shaping this dynamic field. From automation and digitalization to new materials and sustainable practices, these trends are not only enhancing the efficiency and productivity of sheet metal fabrication but are also catering to the growing demand for customized solutions in diverse markets.

The shift towards more integrated manufacturing processes has given rise to sophisticated technologies such as laser cutting, 3D printing, and advanced CAD systems. These innovations allow for greater precision and flexibility in production, making it possible to tackle complex designs that were once deemed impractical. Moreover, the emphasis on sustainability has led to the exploration of eco-friendly materials and methods, reflecting a broader societal priority that manufacturers must consider in their operations.

As we delve deeper into the trends forecasted for 2025, it is essential to recognize the implications these changes have not only on the industry itself but also on the workforce and the overall economy. By embracing these trends, companies involved in sheet metal fabrication can position themselves for success in a rapidly changing marketplace, ultimately contributing to a more efficient, innovative, and sustainable future.

Emerging Technologies in Sheet Metal Fabrication for 2025

In 2025, the sheet metal fabrication industry is poised to embrace several transformative technologies that promise to redefine operations. One of the most significant advancements is the integration of artificial intelligence (AI) and machine learning into the fabrication processes. According to a recent industry report, the adoption of AI in manufacturing could reduce production costs by up to 30%, while also improving accuracy and efficiency. AI systems can optimize the design-to-production workflow, ensuring that resources are used effectively and minimizing waste.

Another key trend is the utilization of advanced robotics in sheet metal fabrication. Cobots, or collaborative robots, are becoming increasingly common on the shop floor due to their ability to work alongside human operators safely. These robots enhance productivity by taking over repetitive tasks, allowing skilled workers to focus on more complex operations. The global market for robotic automation in fabrication processes is expected to grow at a CAGR of over 15% through 2025, indicating a strong shift towards automation in the industry.

Tip: Implementing energy-efficient machinery and renewable energy sources in your fabrication facility can drastically lower operational costs and attract eco-conscious clients. Additionally, investing in training programs for your workforce on emerging technologies will enhance productivity and keep your team competitive in a rapidly evolving market.

Innovative Applications of Sheet Metal in Various Industries

The innovative applications of sheet metal fabrication continue to evolve across various industries, reshaping manufacturing processes and product designs. According to a recent report from the American Society of Mechanical Engineers, the global sheet metal fabrication market is expected to grow at a compound annual growth rate (CAGR) of 6.5% from 2023 to 2028. This growth is largely driven by advancements in fabrication techniques, materials science, and automation technologies.

In the automotive industry, for instance, sheet metal serves critical roles in producing lightweight yet sturdy vehicle components, which enhances fuel efficiency and safety. A study by the International Automotive Manufacturing Association highlights that the use of advanced aluminum alloys in sheet metal fabrication leads to a weight reduction of approximately 40% compared to traditional materials, significantly contributing to sustainability goals.

**Tip:** To optimize sheet metal projects, consider integrating automated laser cutting technologies. This not only increases precision but can also reduce production time and waste, further improving efficiency and cost-effectiveness.

The aerospace sector is witnessing similar transformations, where sheet metal components are essential for building aircraft structures. The increasing demand for fuel-efficient aircraft has led manufacturers to adopt innovative fabrication methodologies that ensure optimal performance and minimal weight. Research indicates that advancements in computer-aided design (CAD) and simulation tools enable a more accurate assessment of material properties and structural integrity, paving the way for smarter design solutions.

**Tip:** When selecting materials for sheet metal applications, always evaluate the latest alloy compositions, as they can significantly enhance performance characteristics while adhering to industry safety standards.

2025 Trends in Sheet Metal Fabrication Technology and Applications

Sustainability Trends Impacting Sheet Metal Fabrication

As the sheet metal fabrication industry looks towards 2025, sustainability trends are becoming increasingly pivotal in shaping manufacturing processes and applications. According to a recent industry report, over 70% of manufacturers are prioritizing eco-friendly practices, driven by both regulatory pressures and consumer demand for greener products. This shift is leading to the adoption of more sustainable materials, such as recycled aluminum and steel, which not only reduce environmental impact but also shrink costs related to raw material procurement.

In addition, advancements in technology are enabling cleaner production methods, with innovations like laser cutting and automated fabrication systems significantly minimizing waste. The World Economic Forum estimates that by integrating these technologies, companies can reduce energy consumption during production by up to 30%. Furthermore, sustainable practices in sheet metal fabrication are not solely about material sourcing; they also extend to energy usage and waste management. Reports indicate that firms implementing circular economy principles are seeing improved operational efficiency, with some experiencing up to 40% reductions in energy costs.

As the industry embraces these sustainability initiatives, it is clear that sheet metal fabrication is not only evolving to meet current environmental standards but is also positioning itself as a leader in responsible manufacturing practices for the future.

2025 Top Trends in Sheet Metal Fabrication Technology and Applications - Sustainability Trends Impacting Sheet Metal Fabrication

| Trend | Description | Projected Impact | Sustainability Aspect |

|---|---|---|---|

| Automation and Robotics | Increased use of automated systems for precision and efficiency. | Higher production rates and reduced operational costs. | Minimizes waste and optimizes energy use. |

| 3D Printing in Metal | Utilization of additive manufacturing for complex geometries. | Reduces material usage and allows for customization. | Lowers carbon footprint by using less material. |

| Advanced Materials | Incorporation of lightweight, durable materials. | Improves product performance and lifecycle. | Promotes recyclability and longer use periods. |

| Eco-Friendly Coatings | Use of sustainable coatings with low environmental impact. | Enhances surface protection and reduces toxicity. | Encourages safe handling and minimizes waste. |

| Smart Manufacturing | Integration of IoT and AI for real-time monitoring. | Increases efficiency and enhances decision-making. | Optimizes resource use and reduces overproduction. |

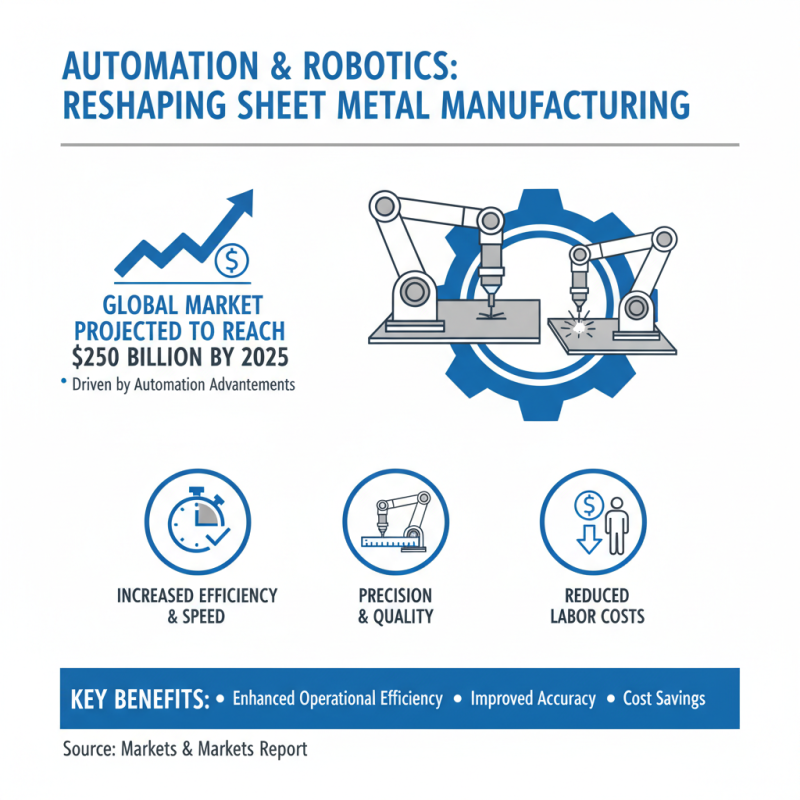

Automation and Robotics in Sheet Metal Manufacturing

In recent years, the integration of automation and robotics in sheet metal manufacturing has significantly reshaped the landscape of the industry. According to a report by Markets and Markets, the global sheet metal fabrication market is projected to reach USD 250 billion by 2025, driven predominantly by advancements in automation technologies. Robotic systems are now capable of performing complex tasks such as cutting, bending, and welding with precision and speed, leading to enhanced operational efficiency and reduced labor costs.

The adoption of automated solutions is not just about increasing production rates; it also addresses workforce challenges. As reported by the National Association of Manufacturers, nearly 2.1 million manufacturing jobs could remain unfilled in the next decade, highlighting the critical need for automation. By leveraging robotics, manufacturers can mitigate skill shortages while also improving product quality and consistency. Furthermore, the implementation of Industry 4.0 principles allows for real-time data collection and analysis, enabling smarter decision-making processes and improved supply chain management. As the industry moves towards greater digitalization and sustainability, the role of automation and robotics in sheet metal fabrication will become increasingly vital.

Future Challenges and Opportunities in Sheet Metal Fabrication

The sheet metal fabrication industry is expected to face a myriad of challenges and opportunities as we approach 2025. According to industry reports, the global market for sheet metal fabrication is projected to reach $243 billion by 2025, driven by advancements in technology and an increasing demand for customized solutions across various sectors. One key challenge lies in the need for skilled labor. A significant portion of the current workforce is nearing retirement, and with newer technologies emerging, there is an urgent need to upskill the remaining workforce and attract new talent. The shortage of skilled workers is projected to hinder production capacity and efficiency if not addressed promptly.

Moreover, sustainability will play a crucial role in shaping the future of sheet metal fabrication. As regulations around environmental impact tighten, manufacturers will need to adopt greener practices to remain competitive. Reports indicate that companies integrating sustainable practices into their operations can see a reduction in costs by as much as 15%, not to mention the positive impact on brand reputation. Adopting advanced technologies such as IoT and AI can streamline production processes, improve waste management, and enhance overall efficiency. Emphasizing these sustainable and technological advancements will not only address current challenges but also open up new avenues for innovation and market growth in the sheet metal fabrication industry.

Related Posts

-

10 Essential Tips for Setting Up Your Metal Workshop Efficiently

-

2025 How to Choose the Best Aluminum Roof Panels for Your Home Renovation

-

2025 Top 10 Architectural Sheet Metal Trends for Innovative Design Solutions

-

10 Essential Tips for Choosing the Best Roof Panels for Your Home

-

Top 5 Benefits of Using Stainless Steel Wall Panels for Modern Interiors

-

How to Choose the Best Aluminum Roof for Your Home in 2025